We understand the massive effect faulty alma laser equipment have on your business

1.Business is not working properly

2.Lose customers

3.Influence market reputation

If you choose a laser repair company that is not very professional, there may be several situations.

*The repaired new laser stack has a short life

* low energy, poor results

*The laser wavelength is not the standard wavelength, the error is greater than ±3nm

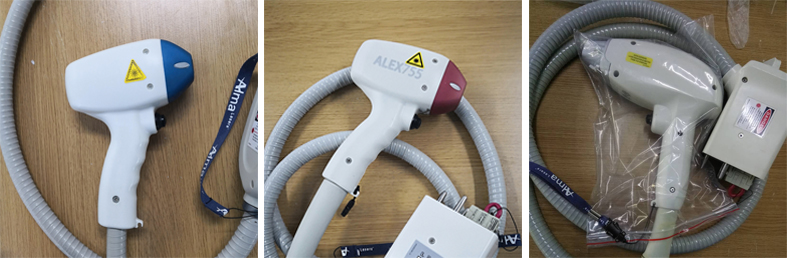

We have full production lines of laser diode stack package, DPSS laser module, laser hair removal equipment and etc. Since 2009, we have successfully repaired more than 500 alma laser handpieces. We have professional technology and rich experience to complete alma laser stack repair and replacement.

*We use the alma original jenoptik laser bars from germany.

* Gold tin packaging technology,high temperature resistance, oxidation resistance

*Professional laser packaging technology,Experienced

We have repaired alma handpiece type

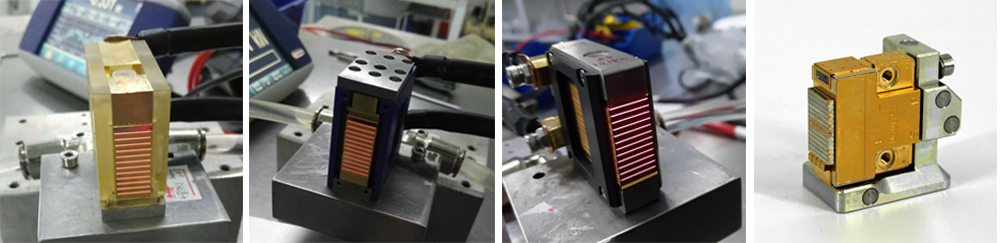

We have repaired alma laser stack type

Company and cleaning lab details:

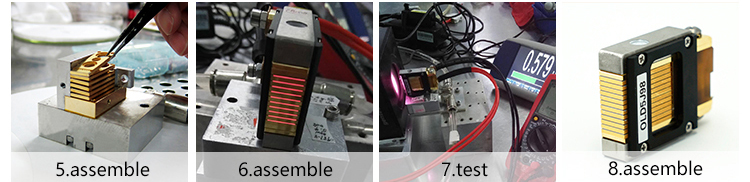

1.Professional laser cleaning lab for laser head mounting, laser stack assemble and also laser handle assemble

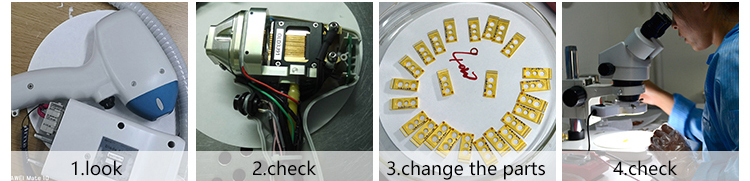

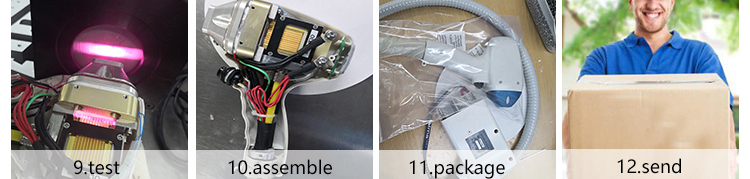

Alam laser handpiece repair process:

With email or whatsapp , you can send us picture or video to show me the problem. When confirm the repair service, the process as:

1.you need send the alma laser diode stack to us, if can not send old laser stack,you need send to us structure design of the diode and dimension details stack. We will repair the old diode or design a new stack to replace the old one.

2.we disassemble the alma laser stack, and test the old laser stack. For the micro channel laser stack, Such as Alma laser, Lightsheer, Syneron. We will test each laser plate one by one to confirm whether there are any one bars still can work. If there have some good bars, the repairing charge will lower. For macro laser stack like most product made in China, we will test whole laser stack together

3.We will mount diode bar to heat sink and assemble diode stack to old or structure in our cleaning lab Our bars and micro channel cooler are import from Germany manufacture. We strictly manage mounting, assembling and testing step during laser stack producing. Every stack will be fully tested and had 8 hours burning test.

4.The Fourth step:

Our experienced technician will reassemble the handle piece. Which include:

a. Install the new laser stack into the handle piece.

b. Clean lens and check the TEC and other parts inside the handle piece

c. Test the power output of whole handle piece.

d. Clean the cover shell of handle piece and package it.

Tips: To pack the laser head or laser handle in a safe box, and make sure safety during delivery, no any damage. Also please drain away water from the laser diode head or handle,make sure no water inside the water road or water tube inside the laser head or handle to avoid further damage.

Generally, the main problem of these diode laser stacks is: Some or all of diode bars were burned.

Followings are some reasons that cause burning the diode bar problem

Temperature

* Using machine for too long time. it causes that the temperature becomes too high.

* The water flow rate is low. It causes the bad heat dissipation.

* The room temperature is a bit higher than normal, when using the machine.

Humidity

* The environment for the machine is too humid.

Quality

* Using bad quality diode bar.

* laser diode bar mounting technology couldn’t reach the standard.

* The electronic control parameters don’t suit for the diode laser stack

Please put a paper list include the following information:

1.Contact person name

2.Company name

3.Address details, include street city name and country name

4.Zip code

5.Phone number

6.Email ID or whatsapp ID that i can contact you when i get the parcel

7.Problem description

Tips: Never write the word laser with the parcel, to avoid some problems as:

1.Customs clearance delay

2.Parcel return

3.High delivery cost

Advice for laser machine maintain:

1.Please change filter once for 6 months.

2.Please add DI water to machine, and 1 month change water.

3.Please drain out water from machine if machine long time no working.

4.Please let the machine take a rest for 5 mins after 2 hours working, please love your machine, and it will also love you.